Electrical systems can pose significant risks to personnel and equipment, with arc flash incidents being one of the most dangerous hazards. An arc flash is a sudden release of energy due to an electric fault that can cause severe injuries, burns, and even fatalities. To mitigate these risks and ensure the safety of workers, an arc flash study is essential. In this article, we will discuss the dos and don’ts of conducting an arc flash study, enabling organizations to enhance electrical safety.

DOs:

1. Engage Qualified Professionals: An arc flash study requires expertise and knowledge of electrical systems and relevant standards. It also can be dangerous as you may be opening energized cabinets for visual inspections. Engaging qualified electrical personnel including consultants with experience in arc flash analysis ensures accurate results and adherence to safety guidelines.

2. Collect Comprehensive Data: Gather detailed information about the electrical system, including single-line diagrams, equipment ratings, conductor lengths, and system configurations and visual verification of actual configurations: settings, catalog info etc.. Accurate data forms the foundation for an effective arc flash study, enabling precise calculations and hazard assessments.

3. Perform Accurate Short Circuit and Coordination Studies: A thorough short circuit study determines the maximum fault currents at various points in the system, while coordination studies evaluate the protective device settings. These studies help identify potential fault locations and ensure proper coordination of protective devices to minimize the arc flash hazard.

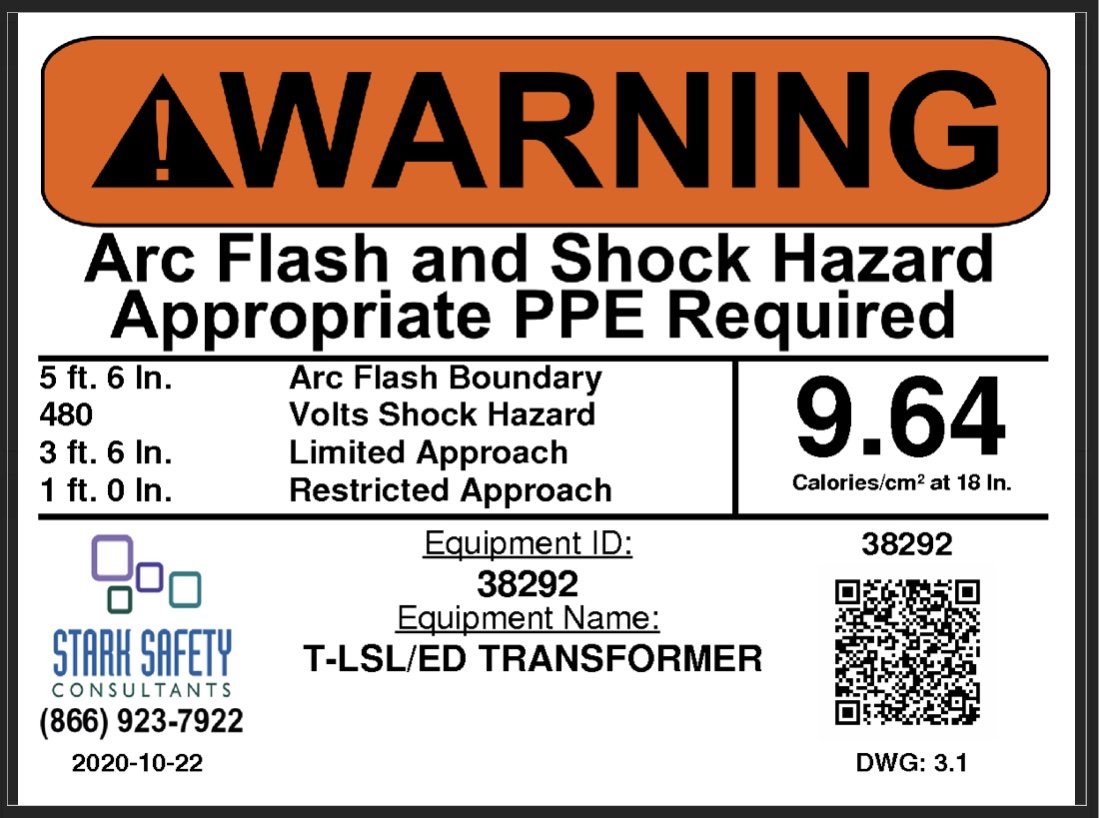

4 Personal Protective Equipment (PPE)/Training: Following the arc flash study, determine the required PPE based on the calculated incident energy levels and arc flash boundaries. Provide proper training to workers on the correct use and maintenance of PPE, emphasizing its importance in preventing severe injuries during an arc flash event.

5. Implement Clear Safety Labels and Signage: Apply arc flash labels to equipment based on the study’s findings. These labels should display relevant hazard information, including incident energy levels, arc flash boundaries, and required PPE. Well-placed warning signs and visual cues help raise awareness among workers and reinforce safety protocols.

DONTs:

1. Neglect Regular System Maintenance: Over time, electrical systems may undergo changes or experience wear and tear. Failing to conduct routine inspections, maintenance, and testing can lead to inaccurate data and potentially hazardous conditions. Ensure regular upkeep and update the arc flash study accordingly.

2. Underestimate Incident Energy Levels: Avoid assuming conservative values for incident energy without proper analysis. Overestimating or underestimating incident energy levels can result in inadequate or excessive PPE, compromising worker safety. Rely on accurate calculations and analysis to determine the appropriate level of protection. Talk to your engineering/consulting team to explain:

- What assumptions may have been made and why?

- Ask about IEEE “2 second rule” , has it been used and where/why?

3. Disregard Training and Education: Workers must receive adequate training on arc flash hazards, safety protocols, and emergency procedures. Ignoring the importance of training can lead to an uninformed workforce, increased risk of accidents, and compromised safety. Regularly conduct refresher courses and keep employees updated on new industry standards.

4. Overlook System Changes and Upgrades: Any modifications or upgrades to the electrical system can impact its arc flash characteristics. Failure to reassess and update the arc flash study after significant changes can result in outdated information and increased risks. Ensure that the study is periodically reviewed to account for any system modifications.

5. Neglect Continuous Improvement: Electrical systems evolve over time, and new technologies or practices may emerge to enhance safety. Regularly evaluate the effectiveness of implemented control measures, review incident reports, and stay updated with industry advancements. Continuously improving arc flash prevention measures is crucial for sustained electrical safety.

Conducting an arc flash study is a critical step towards mitigating the hazards associated with electrical systems. By adhering to the dos and avoiding the don’ts mentioned above, organizations can enhance workplace safety, protect personnel from arc flash incidents, and ensure compliance with relevant regulations. Prioritizing accurate data collection, engaging qualified professionals, and providing comprehensive training will help establish a culture of safety and reduce the risk of arc flash accidents in electrical environments.