Arc Flash Study: Do’s and Don’ts for Enhanced Electrical Safety

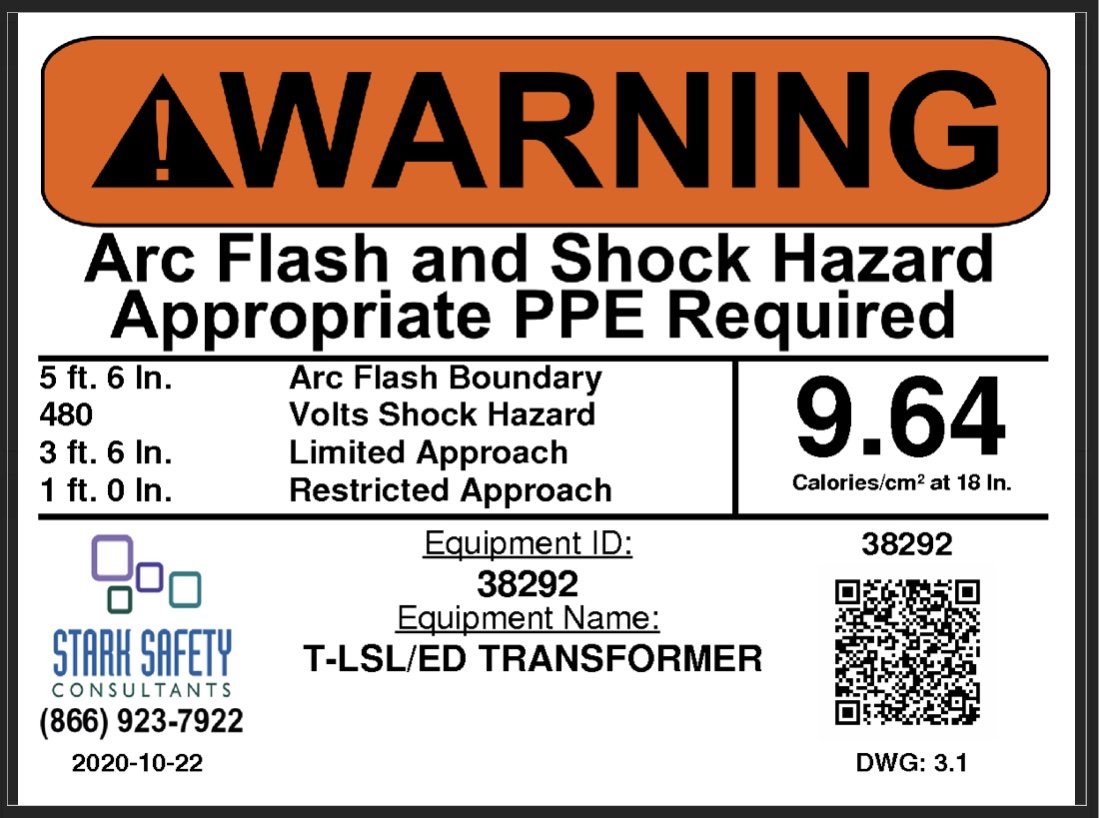

Electrical systems can pose significant risks to personnel and equipment, with arc flash incidents being one of the most dangerous hazards. An arc flash is a sudden release of energy […]